RCC’s Mechatronics students learn futuristic technology, trends

Mechatronics is high-tech with a big paycheck, and it’s the future of engineering. Today students at Robeson Community College are busy learning about the tools of the trade, for the industry of tomorrow.

What is mechatronics exactly?

It’s a branch of engineering that brings multiple disciplines together – mechanical, electrical, computer, and robotics engineering. It’s robots, artificial intelligence (AI), programmable logic (PLC), and industrial automation.

And most importantly, as Daniel Jimenez says, “It is a lot of fun. It takes time to learn this stuff, it is not common knowledge, but once you get it, it’s really cool.”

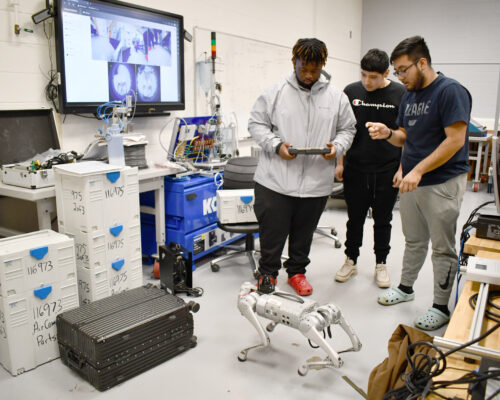

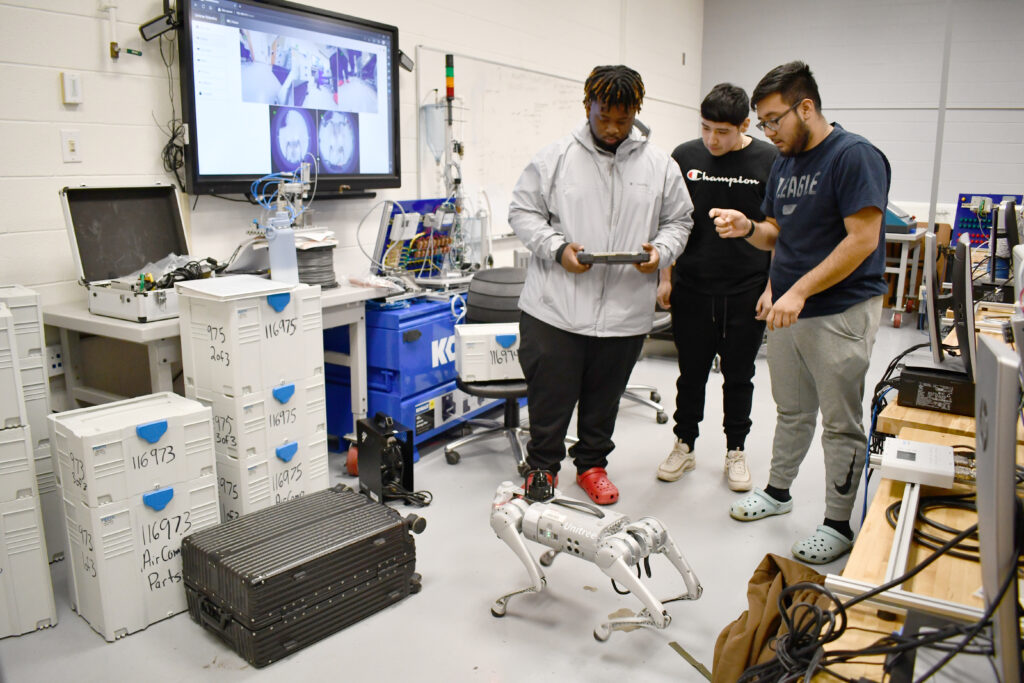

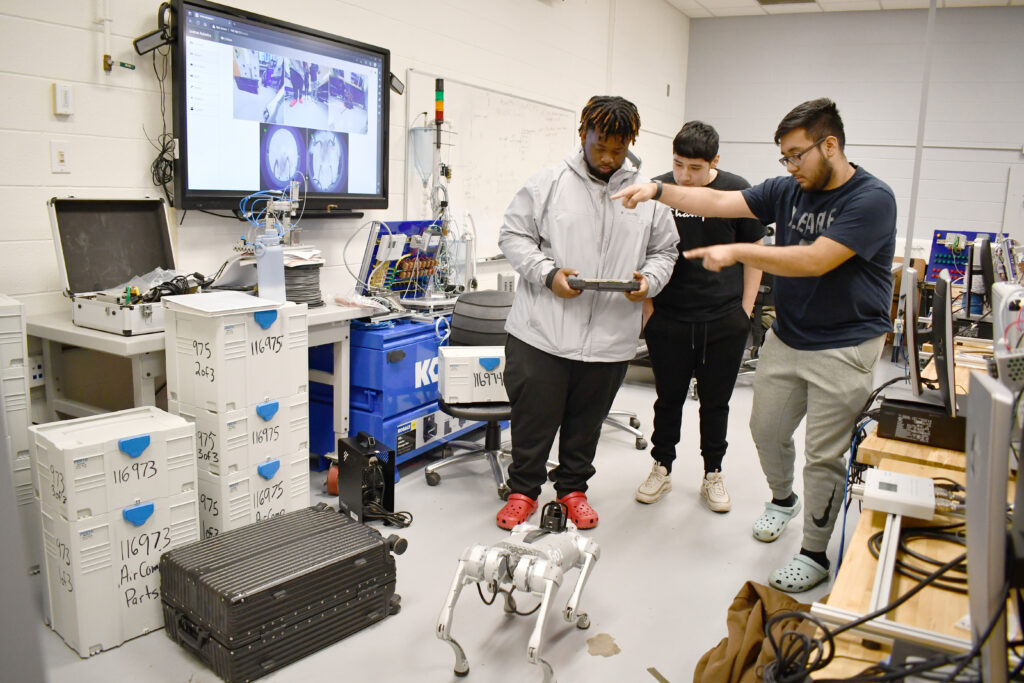

Students get to learn a variety of things, including how to use the robot dog that arrived last summer.

“With the robot dog, the opportunities are endless,” stated Joseph Nation, an instructor in the Mechatronics program. “Companies like Amazon for instance, if you think about their distribution system, we can tie some of what they do in their facilities with the robot dogs.”

“With the robot dog, the opportunities are endless,” stated Joseph Nation, an instructor in the Mechatronics program. “Companies like Amazon for instance, if you think about their distribution system, we can tie some of what they do in their facilities with the robot dogs.”

“This dog can actually be programmed to follow a certain route,” said Nation. “All kinds of different motions can be programmed into it, it has different AI capabilities, so that’s some of the ways we try to demonstrate how this type of technology can be used in the workplace, along with lots of other technology.”

“It also has a lot of other uses too,” Dorian Walters, a second-year student in the program said as he chimed in. “It can go into search and rescue and be used by law enforcement. It’s very high tech and it also has microphone capability to it.”

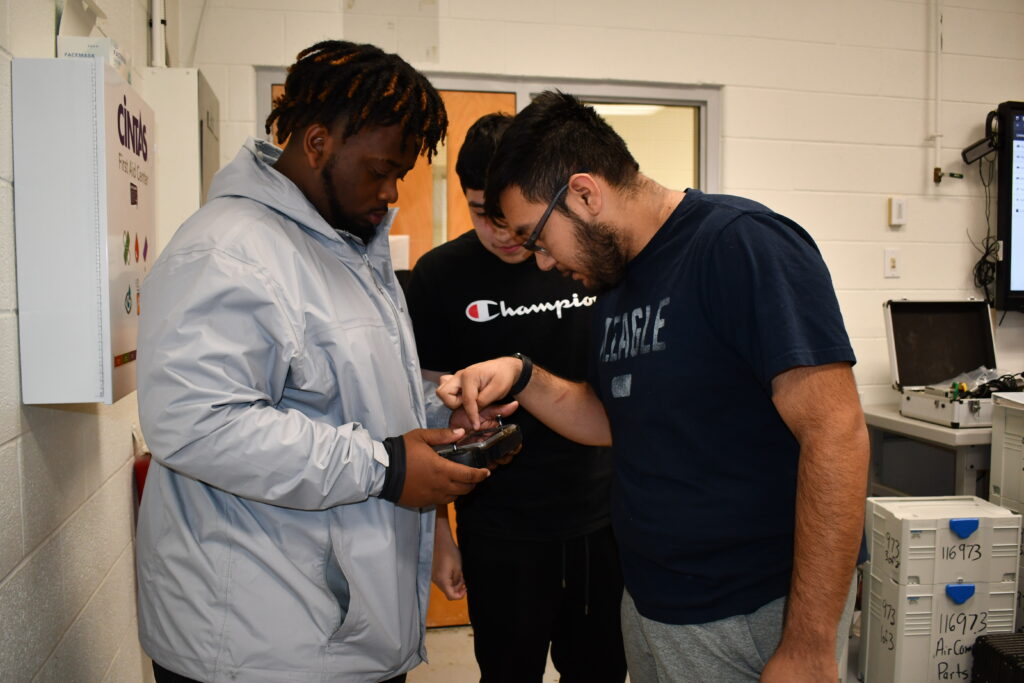

Students demonstrated how the robot dog can move, showing how the cameras installed could be viewed from the remote.

“We can see everything the dog can see,” RCC student Jonathan Gabino said. “It also has sensors on each side, so it won’t hit anything. The robot will try to avoid it.”

“It is a great resource for students,” Gabino said as he continued his demonstration. “It is very complex with all the different processes it has designed into it. It is very tech savvy.”

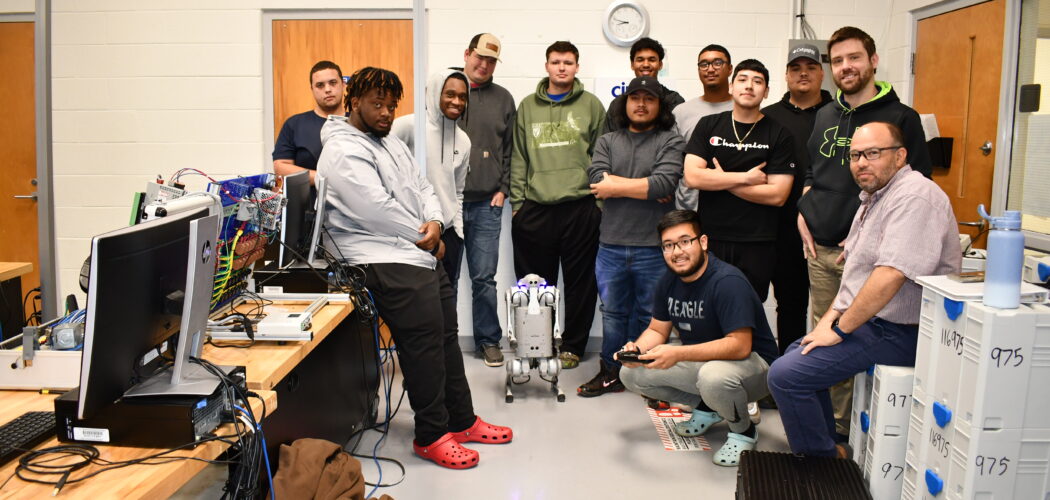

The robot dog has also been a great recruiting tool for the mechatronics program, which was named the program with the highest percentage increase at Robeson Community College in 2022.

“We are drawing attention across campus and in the community,” stated Heath Worriax, discipline lead for the program. “People are taking notice, especially students.”

“And because we’re #1,” Nation added, referring to two students winning gold at the North Carolina SkillsUSA mechatronics competition who went on to compete in the national competition, taking a 4th place finish.

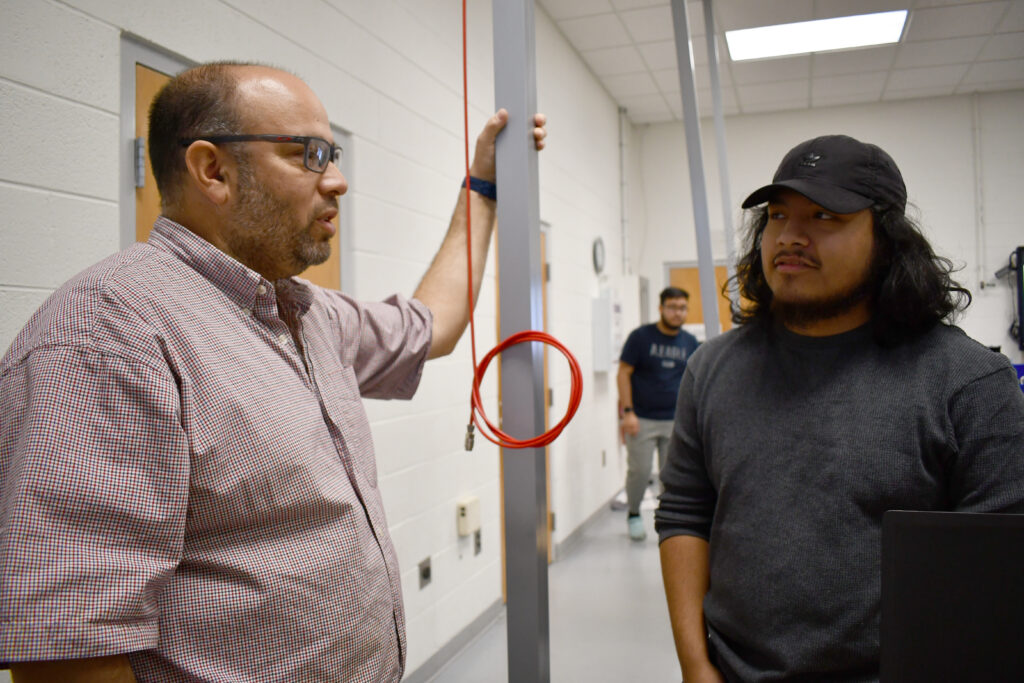

The major win and success of Jonathan Gabino and Allan Inestroza at SkillsUSA have put the mechatronics program at RCC on the map. It has also motivated others to enroll in the program like Rylan Oxendine, David Jimenez, and Daniel Bravo. These students, along with others, are taking the time to meet outside of class with instructors to practice and prepare for the 2023 competition.

“The Mechatronics division is preparing,” said Gabino. “We want to go back to Atlanta… It’s a good experience…it really shows people that we can make it out of Robeson County and shine in high places.”

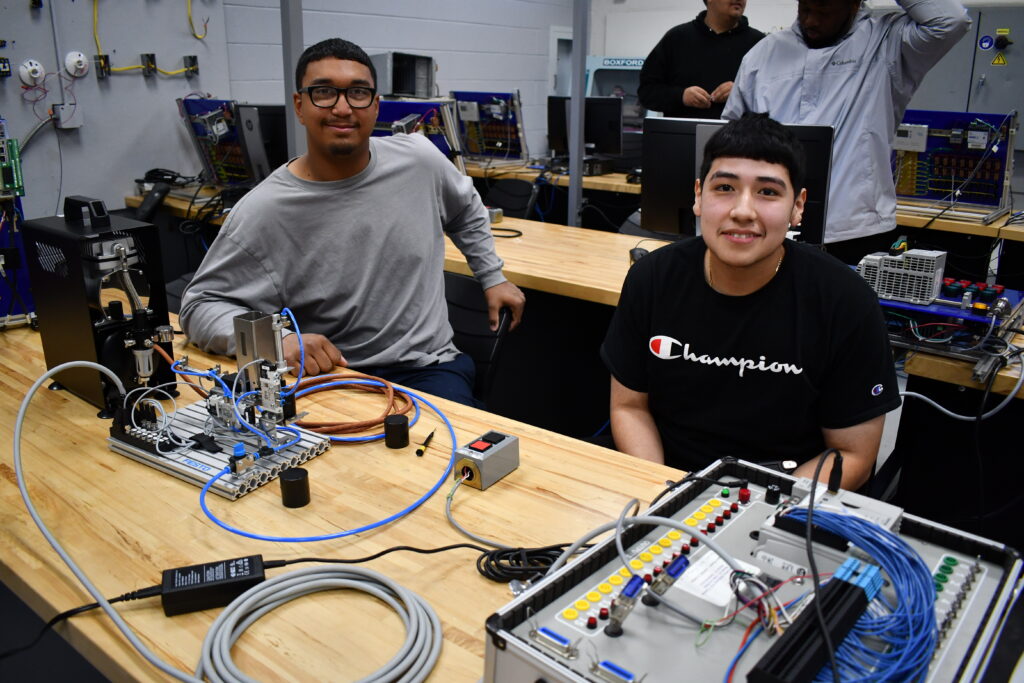

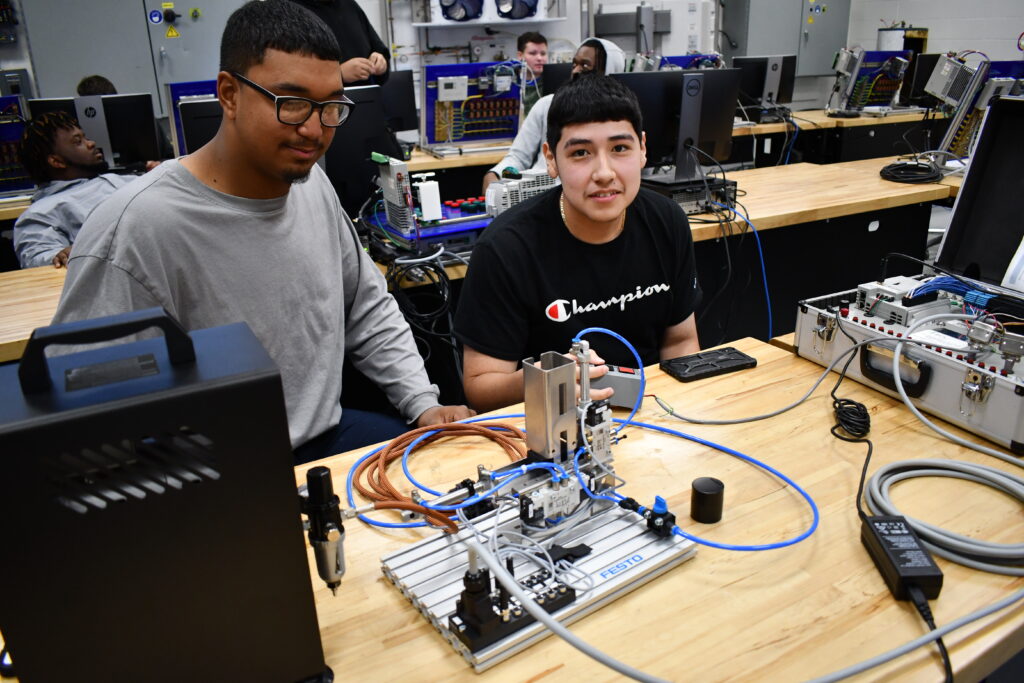

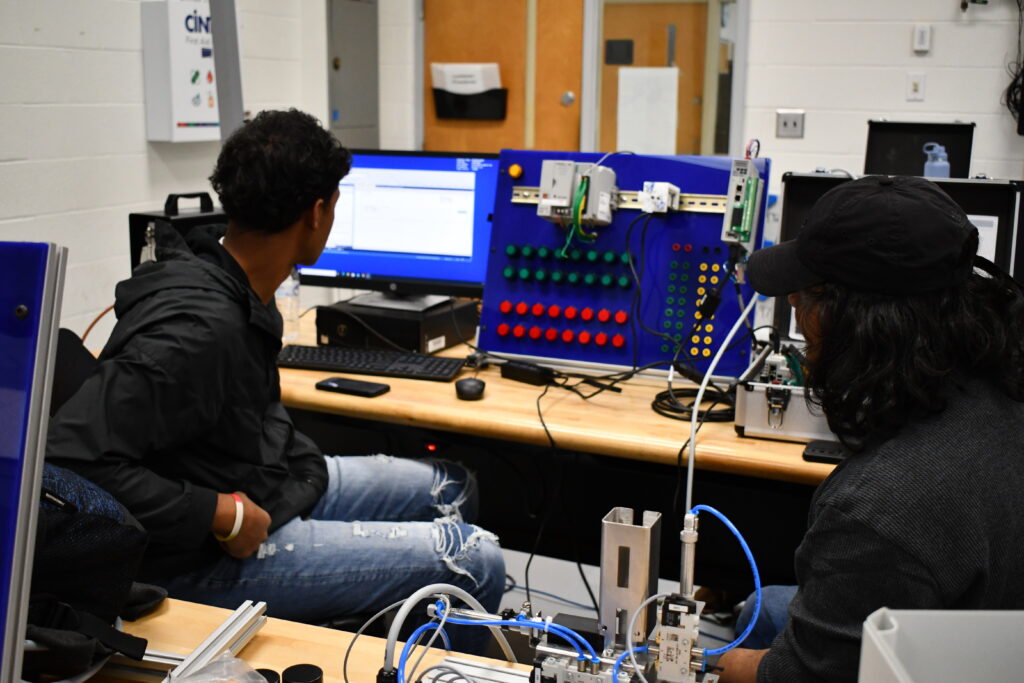

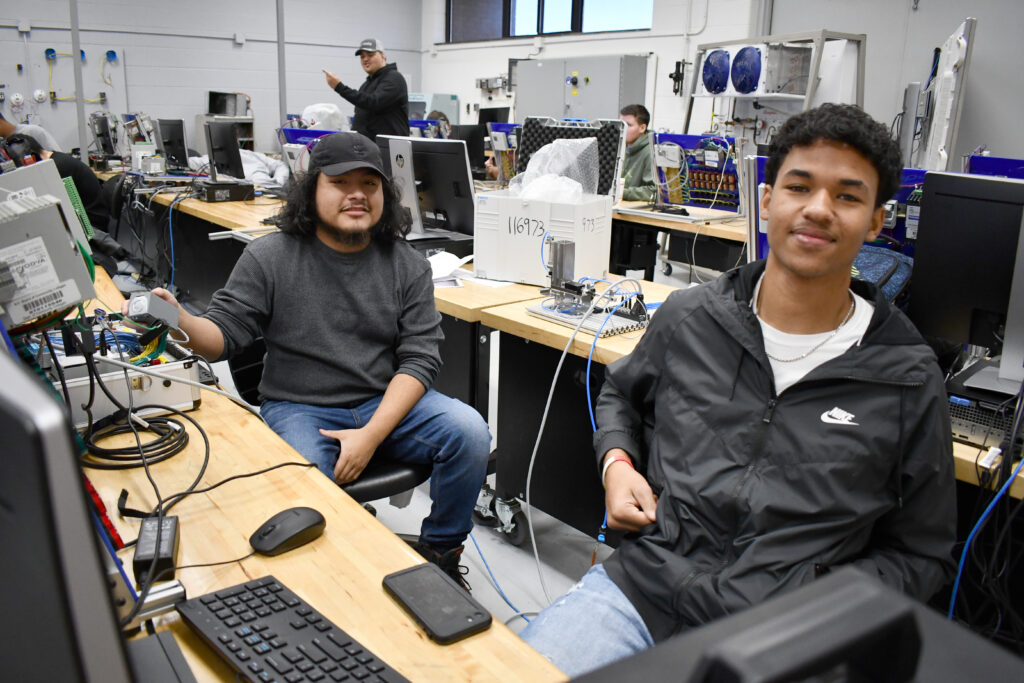

Left, David Jimenez and right, Rylan Oxendine, work together to prepare for the 2023 SkillsUSA competition

For Ryland Oxendine, the chance to compete in SkillsUSA was not something he could overlook.

“It was an opportunity I couldn’t really pass up, to be able to use what I’m learning in class to show off my skillset at the state level and possibly the national level,” said Ryland Oxendine, a dually enrolled student at RCC and the RCC early college. “Plus, I can use it on my resume and possibly get into a better college because of it.”

David Jimenez adds, “I have learned about the job opportunities that come from competing in SkillsUSA, it’s also a chance to expand upon my skills.”

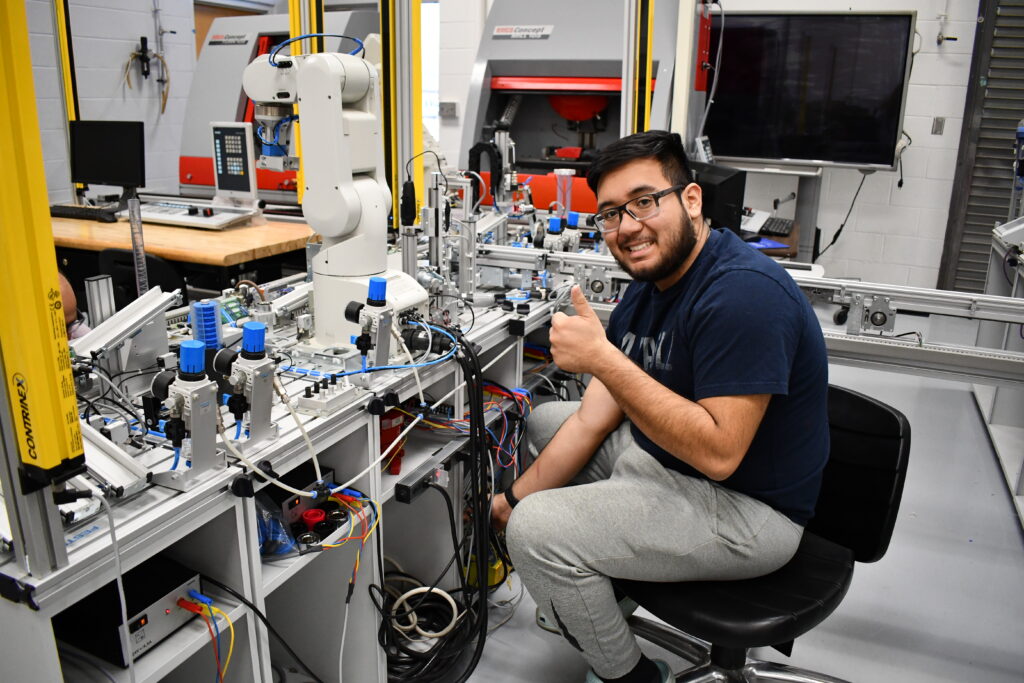

When the students meet to practice for the upcoming competition, they work in pairs with a PLC suitcase, testing various scenarios in which they can program parts to move items. It’s similar to what they do in the labs, just on a smaller scale.

When they are in class, students work in state-of-the-art facilities, and thanks to a recent donation from Mountaire Farms, they are now able to train using large, full-size industrial-grade equipment.

“It was over a million-dollar donation,” stated Nation. “Everything is industrial grade and industrial sized.”

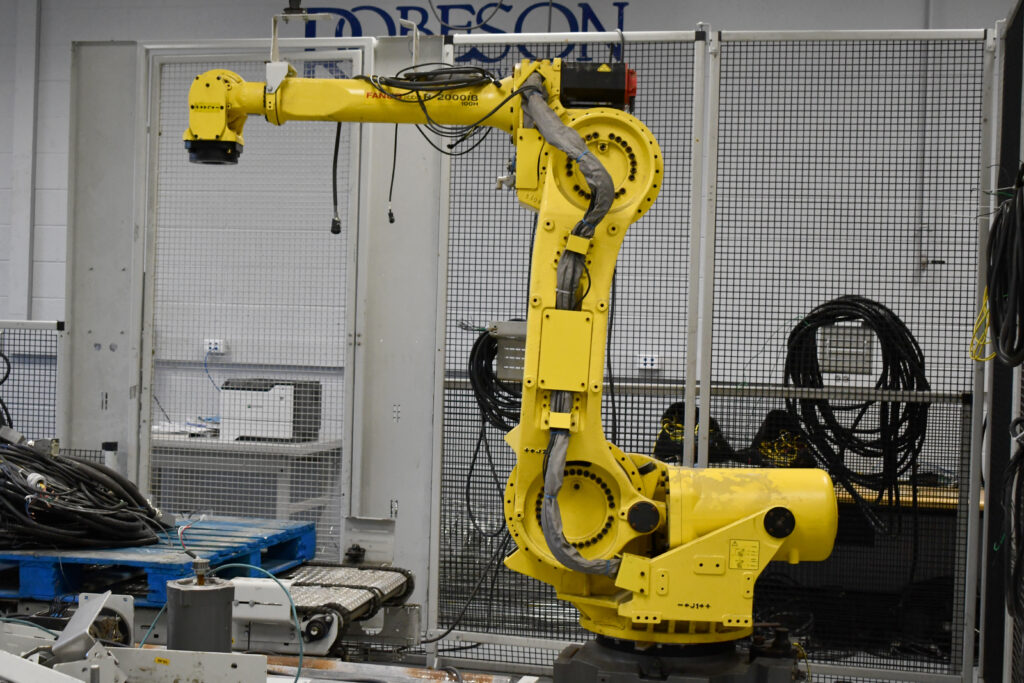

The newly reconstructed classroom is an amazing sight to see. What was once a computer lab has now been transformed into a full-scale manufacturing production lab, complete with robots, motors, control panels, conveyors, light curtains, and electrical cabinets.

“Mountaire Farms has helped us to kickstart our very young mechatronics program,” said Nation. “We can now utilize the equipment in multiple classes for our program.”

Worriax agrees, saying, “The donation has helped us to be able to incorporate many disciplines into the mechatronics class – maintenance, electro pneumatics, and even software programs… So instead of being stuck in one discipline, we can go into multiple disciplines in one classroom.”

“We are working on other ideas for the program,” Worriax said. “The donation has made a significant difference in being able to give our students the hands-on experience they need to be successful once they graduate.”

Nation and Worriax are extremely grateful for the donation, saying it has truly made an impact on the program and students.

“Thank you, Mountaire for your kindness and generosity,” stated Nation.

“We are so thankful for the donation from Mountaire Farms, our students love having the ability to work on the equipment, it changes the dynamics of the classes and students look forward to getting to work on the machinery,” said Worriax.

And, the students really do love the newly donated equipment. Some of the students recently gave a tour of the lab on Facebook Live, explaining the various stations with enthusiasm and pride.

“First of all, we want to thank Mountaire for donating all this to us,” said Dakota Collins, a student in the program, as he explained the HMI screen on a panel screen and how it can be used to move the programmed robots. “It takes a lot of wiring… you’ve got to know exactly where each wire goes.”

Marjavis Alston, a student at RCC, explained about light curtains and how the conveyer belts work.

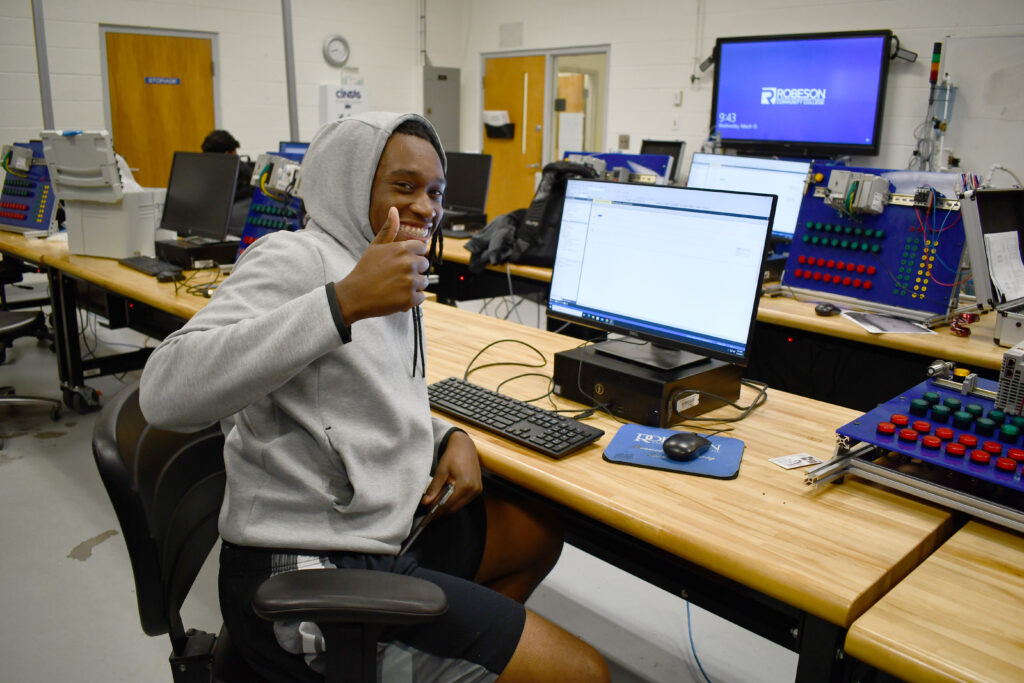

“The motors are running off 480 volts and they run on various frequencies,” Alston said, who is already working in the industry for Elkay. “It’s a great experience to see it in class and then be able to apply what you learn at work.”

Caleb Cox, another mechatronics student, showed one of the panel screens, saying “We will eventually be able to run this whole setup from this panel, eventually we will have all the emergency stops all tied together… we’ve been working with the cables to start working towards that.”

Gabino completed the tour, showcasing the giant robot in the room, standing at more than six feet tall.

“Students like me will be able to joggle the robot around,” said Gabino, as he used the remote controller to demo the machine. “It rotates very fast, so that’s why we have all this caging around to make sure we don’t break anything or hit anything, there’s a lot of safety involved…but this is the future. A lot of places like Pepsi and Amazon use robots for production, so being able to troubleshoot, being able to know how to operate, knowing the rules needed to actually operate the equipment helps you out with many things.”

Instructors say it’s their goal that students will become qualified for as many jobs as possible in this diverse field of mechatronics.

“They will have options,” said Worriax. “Mechatronics is the fastest growing field of engineering in the United States. The career outlook is bright. There is a high demand for this specialized skillset, most of our graduates start out making $25 per hour or more.”

If you are interested in learning more about the Mechatronics Engineering program at Robeson Community College, please contact Heath Worriax at hworriax@robeson.edu or 910-272-3469. You can also visit https://www.robeson.edu/industrial-technology/mechatronics.